Top Lists

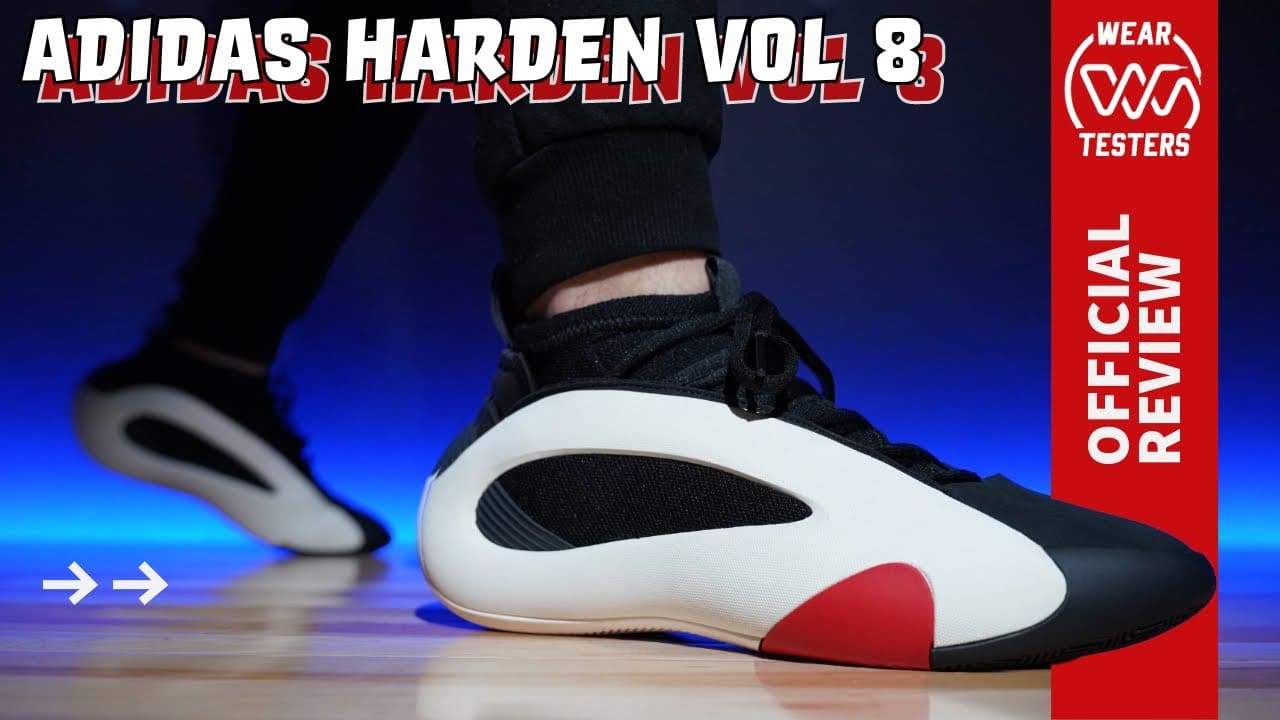

Most Popular Basketball Shoe Reviews

See more Basketball Shoe Reviews

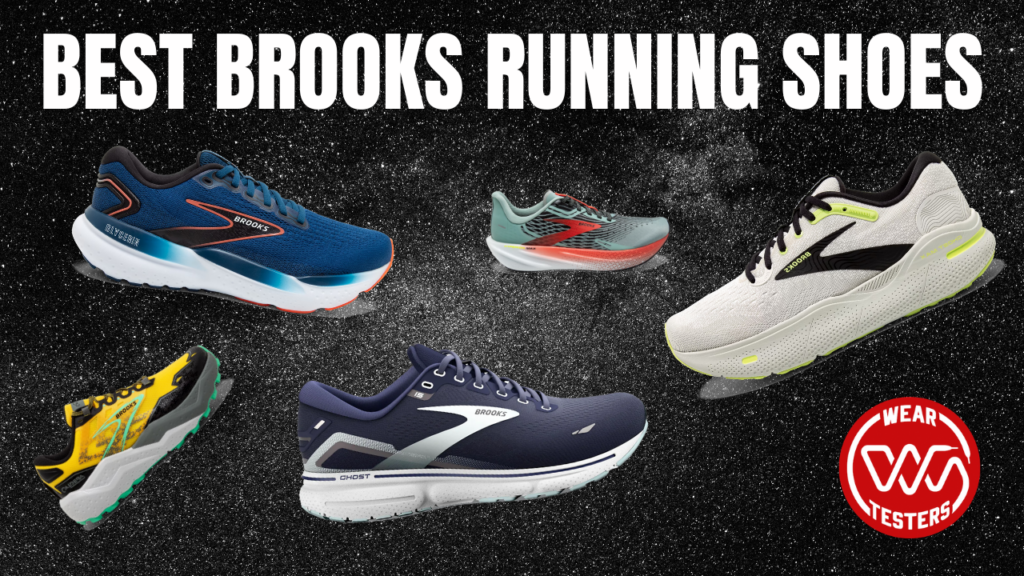

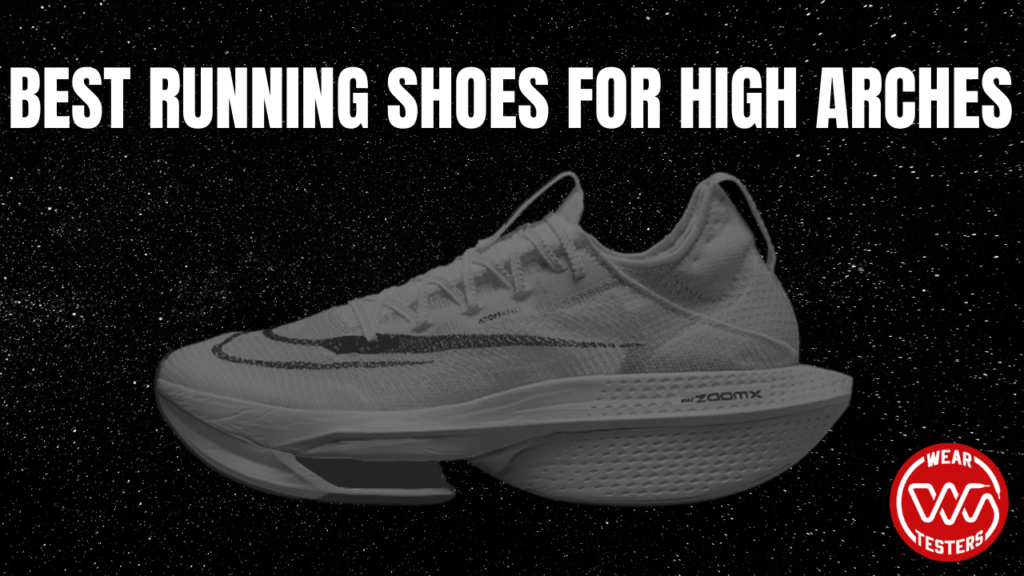

Best Running Shoes Lists

Recent Running Shoe Reviews

Best Volleyball Shoes Lists

Recent Volleyball Shoe Reviews

Best Cross Training Shoes Lists

Recent Cross Training Shoe Reviews

See more Cross Training Shoe Reviews