Last month, WearTesters was invited to try the adidas Futurecraft Loop, a 100% recyclable performance running shoe. We were given the Futurecraft Loop alongside 200-ish influencers. Based on what I heard from the others in attendance, most articles about this shoe will focus on the recycling side of the shoe. This article will be what WearTesters does best, an in-depth performance review.

You can also see the Futurecraft Loop on our Best adidas Running Shoes list.

While the Futurecraft Loop won’t release publicly until summer 2021, a public beta is coming this fall. The public beta will be free, but you’ll have to apply for it. We’ll share the public beta details on WearTesters as soon as we get them.

First a little background. Some people called these a concept car for shoes, but it’s not. This is an actual shoe that Adidas is fine-tuning for release. This is a first-generation version where the brand needs wear-testing feedback. Adidas will keep modifying the sneaker until they go into production for the summer 2021 release.

The reason the shoe is so interesting is that it could be a game changer for the sneaker industry. Recyclable sneakers may create new business models in the footwear industry — think shoe subscription models where you pay a monthly fee and always have fresh kicks, or a trade-in model where you get a lower price on your new shoes by trading in the old ones (like Apple does with iPhones).

For this review, I ran 60+ miles on pavement, trails, and in a Flash Flood warning–level rainstorm. I also wore the Futurecraft Loop to Legoland, around NYC, and as my everyday kick-around shoes for a month. I wore them a lot. Why? Because Adidas asked me to. They asked everyone who got the shoes to run them into the ground for a month and return them. When the shoes are returned to Adidas, they will be washed, ground to pellets, and melted into material that will be used to make a new pair of shoes. At this point, they can only use the recycled portion to create 10% of the second-generation model, but they’re actively working to improve that. Mostly, they want to see how hard use will affect the materials and thus the second and third generations of the Loop. After I send these back, I’ll get the second-gen version to test. We’ll update this article or write a new one once we’ve had a chance to see how the second-gen Futurecraft Loop performs.

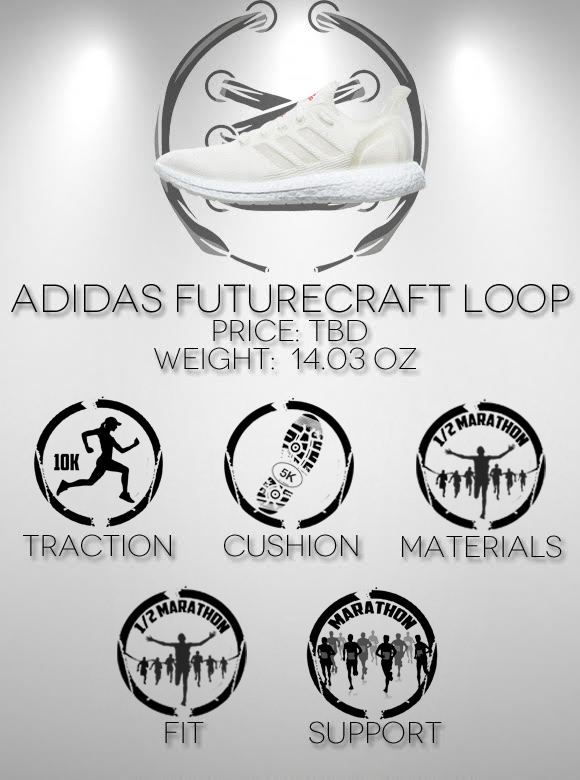

We’ll start with the materials because they’re the big story. The Futurecraft Loop is made from 100% reusable thermoplastic polyurethane (TPU) with no glue. They’re plastic shoes. The plastic is used in a much different way then you’re used to: spun to yarn, knitted, molded, and clean-fused to a BOOST midsole using Adidas Speedfactory tech. Adidas needed numerous technical innovations to make this happen. The one that really stood out to me was the TPU yarn. At first, it feels like you’re wearing a fuse-era basketball shoe. However, the TPU yarn breaks in over time in a way fuse doesn’t. It never got as comfortable as a knit shoe, but I did feel like it developed a nice one-to-one fit. The breathability of the yarn is another nice surprise. You don’t expect it, but the yarn’s airflow stacks up nicely against typical performance running shoes.

From an aesthetic perspective, Adidas made the Futurecraft Loop with the TPU in its raw state, so the color looked either bright white or slightly yellow depending on the lighting. Adidas left the TPU raw to better understand what happens to the materials as they age and are recycled to create the second-gen model. Adidas can color the TPU and showed us examples of red and blue versions. Apparently, the colors will get progressively darker as the shoe transforms from one generation to the next, so you’d get a slightly different shade each time the shoe was recycled.

The Boost midsole mold was reused from the Adidas Ultraboost 4. The Futurecraft Loop feels great on the road. The Boost is a different formulation than the normal version from the BASF Corporation. Adidas had to recreate it since this version needed to come from the TPU used on the rest of the shoe. Though a different formulation, the typical Boost bounce is there and there’s no real difference in feel from the Boost you have in your closet. Strangely enough, this new Boost does repel dirt better than previous iterations – random I know.

As a nice addition, the insole is cushioned using Boost. No complaints here on that upgrade from typical EVA foam. I did have complaints about the top of the insole. It’s the biggest drawback of the shoe and something that needs to be improved prior to launch. The insole covering is fibrous and rough. I think Adidas roughed up the yarn fibers so you don’t slide around. Unfortunately, the insole doesn’t smooth out over time as the cushioning molds to your feet. That means the insole is always slightly uncomfortable. I did get a blister on one of my toes after a few days of back-to-back running, and the bottom of my feet would often feel beat up after a long run. The cushion is typical of other Adidas models with boost, but they must improve the insole so long-distance runners don’t have issues.

The Futurecraft Loop fits true to size and wide footers shouldn’t have any issues. Because they’re made of TPU, the shoes are a little stiff for the first week, but they do break in and the TPU yarn molds to the sides of your feet. My only issue here is that the laces weren’t quite long enough and didn’t have enough stretch. The laces also slipped apart without a tightly pulled double knot. When I asked, the Adidas designers told me this is something they are actively working to improve. I was told making plastic laces is extremely hard, but they’re making progress on creating something that will function as well as normal laces.

This is one area where the Futurecraft Loop excels versus typical knit runners like the Ultraboost 19. While there’s no real heel counter, you do sit slightly inside the boost midsole. The TPU yarn is also very strong and stiff in the heel. While it does break in, it never gives as much as regular knit. Even on the most uneven trails filled with tree branches, I always felt securely on top of the midsole and was never in danger of tweaking an ankle.

Going into my testing, I was worried about the traction. After all, the outsole is made of TPU. I usually associate plastic with slipping and sliding on any slick surface. I started my first rainy run with trepidation. Luckily for me, the team at Adidas managed to create a TPU outsole soft enough that it almost works as well as rubber. The outsole had more than enough traction for completely wet streets, various trails, and concrete/pavement. The only time the traction didn’t grip well was if I ran through a puddle and the outsole got wet while the rest of the ground was dry. For 5–10 steps post-puddle, I had to be careful with my footing. Once the wetness was gone, the shoes returned to their normal traction. Overall, a fantastic effort for a plastic outsole. It does yellow (intensely) but durability shouldn’t be an issue. It didn’t wear out any faster than the regular Continental rubber outsole Adidas uses on the Ultraboost line.

The Adidas Futurecraft Loop feels like a stiffer, slightly less cushioned version of the Adidas Ultraboost 19. I’m excited to see how Adidas improves the laces, insole, and traction. I’m also ready to find out how the second-gen model performs, how Adidas does color on the Loop line, and how this may change Adidas’ business models. I’d recommend the Futurecraft Loop if you love the 100% recyclable concept or if you’re a serious runner that loves Adidas shoes. Give these a try when they go to public beta. Also, there’s a chance this may be the one shoe industry future (of 14,000,605 possibilities) in which the environment wins.

Awesome review Drew. Who knew plastic could be applied to so many different designs for material use on a shoe? And furthermore, being recyclable makes this a huge win.

What does the “10% to create the second generation model” part mean? That sounds really low, almost insignificant, but at the same time I think I’m missing something.

It means that right now the recycled components of the 1st shoe can only be 10% of the 2nd shoe. Adidas is working on that so that number will increase over time.

Hey drew,follow up question from guy above,does adidas offer the explanation on how do they recycle the shoe??the amateur in me imagine that after they wash it ,the shredded the shoe into a fine plastic then starting the procces of creating the next shoe,obviously its not that simple,so during the unveiling do they also provide which part that can or cant be recycle??

@homer45 they showed us a video. After washing it, they just throw the whole shoe in a big shredder. They showed us what all those pieces look like afterwards too and it just looks like tiny chunks of the shoe. After shredding them, they melt all the components back into TPU that will be reshaped into various components of the next shoe. Pretty crazy process overall that I’d love to see in person one day.

Ahh ,thanks for replying ,and of those shredded shoe/melting pot of tpu ,they could only procces 10 percent of it??for now anyway,what is their difficulty ??you know ,to eventually make them 100% recycleable

They will shred all those shoes, then run them through a pelletizer to turn them into plastic pellets. All recycled materials are stored together. They will be mixed with virgin materials to form the shoes.

What they mean by using only 10% of recycled material is… for example.. if the 2nd gen shoes weighs 10oz, 9oz virgin pellets is mixed with 1oz of recycled pellets, to form the shoes.

But they run production by batches. So if for one batch they will use 100kg of plastic pellets. The mixture of pellet material will be 90kg of virgin pellets mixed with 10kg of recycled pellets.

The process of shredding, pelletizing, and mixing of plastic pellets can all be searched in youtube for a clearer picture of process

So no, 10% does not mean only 10% of shoes could be recycled. They will recycle every part of the shoe and store them together.

Its just the mixture of the 2nd gen shoe will only be using 10% recycled pellets and 90% virgin pellets to form 100% of the shoes

Cool feature of Drew, able to sneak in a TWSS in there.

Interesting beta test. There’s just a lot of experimental elements to this shoe — materials and construction. I think the upper intrigues me most. Wouldn’t want to encourage another age of plastic uppers (albeit knit), but sustainability, and apparent functional potential make it seem like it can have its place in future products.

@cheese got it,thanks for the clear explanation

Very interesting concept from adidas and great review from Drew, thanks!

It’s strange to see cushion being the worst aspect of a Boost kicks… =)

Wonder how the insoles would work if you flipped them upside Down (and obviously left to right to fit)

@homer45 They turn 100% of the previous shoe into new TPU. Currently that 100% becomes 10% of the next shoe but that 10% number will continue to rise as they figure out how to make every component out of recycled material. What they’re doing has never been done before so they’re having to innovate a ton.

Thanks for the explanation,i vaguely understand the concept of recycle ,but with cheese explanation ,and yours i understand them christal clear,so assuming the concept mature enough,and the tech are refined to the point it will not need new plastic ,adidas could theoratically make 100% sustainable running shoes