One of the most difficult aspects of product creation is sourcing a factory that suits your production needs. Whether you’re looking to print 50 T-shirts for a family reunion or 30,000 pairs of basketball shoes, the variables in producing quality goods can be daunting.

The two extremes of getting the sourcing equation right would be to either a) work in product creation for decades with multiple partners so you understand the ins and outs of quality production facilities or b) simply pay someone a chunk of change to do it for you.

Short of being an expert or paying an expert, you should learn a few basics before you make the plunge.

Is the Juice Worth the Squeeze?

When I was at Nike, the smallest of pairs a single color of a shoe could do (MOQ or minimum ordered quantity) was 30,000 pairs. That was a general, of course, but the reasoning for MOQs are based on efficiency. In order for a factory line to produce high volumes of shoes, hundreds of people are organized against on task. The set up for this large team could take months of preparation. Management team have to coordinate all of the logistics – raw goods and materials, worker shift changes, complexity of construction, etc – and pad their calendars for any given disruption – cancelled order or earthquake.

Once the line is set up, the team works tirelessly on the project assigned. The more shoes you make with the set up, the more profitable you are. It’s like running the 3-Man Weave at practice. Your team only needs 30 seconds to set up. Once you get started you can run the weave for 6 minutes. The set up was worth it. But what if you only ran the weave twice – for 30 seconds?

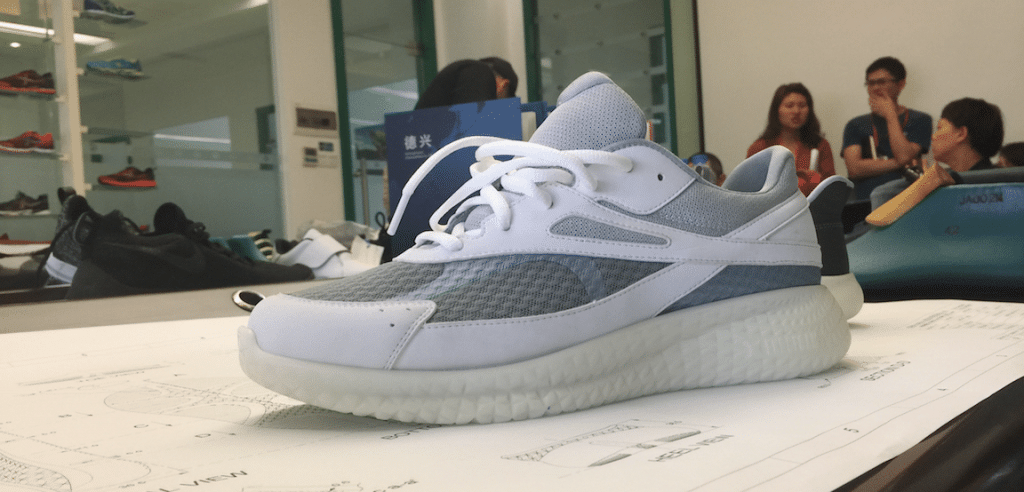

Lower MOQ projects are possible if you understand the roadblocks factories face when working on product. When my older brother needed wider shoes after developing Type 2 Diabetes, I couldn’t let him just any orthopedic shoe. So I partnered with a factory to build an elevated execution of a shoe that was already in production.

Factories equipped to do complicated molds and construction techniques are often the factories with higher MOQ orders. Factories with lower MOQ orders tend not to have complicated set up needs, so they can change from one product to the next. Setting up a 3-Man Weave is a lot less trouble than running an 8 team tournament.

Understand Your Priorities

Ten years ago the landscape of production was fairly basic. If you wanted low cost goods with basic techniques, you’d go to Asia – especially China – and you wouldn’t expect great quality. If you wanted high quality goods, you would go to Europe – especially Italy – but you might struggle with service. However, if you had fairly simpler construction methods, you had options in South America, India and Southeast Asia. There were always exceptions to the rules, but industry had assumptions that everybody understood.

Today, you can find low cost manufacturing in Europe and high quality manufacturing in China. Because there are so many brands and customers around the world, factories needed to diversify their offerings in order to make everyone happy. Chinese factories needed to hire Italian last makers and stitchers in order to build luxury goods properly. Italian factories bought Chinese machinery for simpler tasks that eased production. Study as much as you can about what’s out there today.

This doesn’t mean that every factory can do everything now. But the landscape is more complicated. So designers and brands need to have a better idea as to what’s important about the product that they are creating. Is it cost? Calendar? Quality? Innovation? Shipping standards? Sustainability? Quantity? Once you know what’s important or special about your product, you can position your questions to potential partners so find an appropriate match.

你对英语很满意吗?

I have never worked on a project where everyone shared the same native tongue. While language barriers in the real world are becoming less significant (you may have used Google Translate to read the heading of this section), the language of business adds a great deal of complexity. The average translator has no problem telling you where the closest bathroom might be, but the translation for ‘the compression set of a particular foam at high temperatures after weeks of heavy stress from a 280 lb college freshman’ requires linguistic, engineering and cultural understanding.

You can be a native Chinese speaker or fluent in Italian but that may mean little if you aren’t versed in the engineering or business of making shoes. Your key to success often rests in the factory’s ability to communicate in your native tongue while understanding your business and cultural needs.

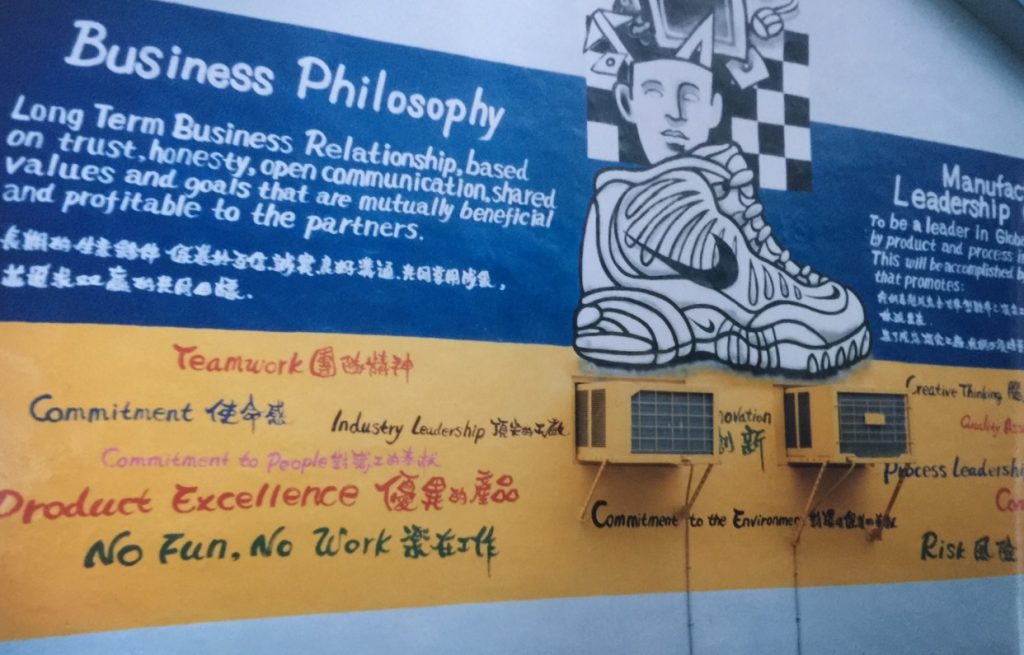

At Nike we would spend hours communicating the marketing plan and the consumer lifestyle to factories in Asia so they would understand the importance of all of our decisions. When they understood our customers, athletes, retail and culture, they could help us make better decisions along the way. The average factory worker in Guangzhou didn’t know why basketball shoes were important to high school kids in America.

This level of sharing let the factory know where we would spend marketing money to support the project that they were working on. If you tell a factory that the shoe they were working on would be supported by a multi-million dollar marketing campaign, their level of effort will improve. Your project may not include the next Lebron James, but your factory counterparts should understand why you think the project will connect with your consumers so they become an extension of your team – not just another transaction in the process of doing business.

Jesus, Take the Wheel

At some point you’ll need to decide how much interaction you want to have in the development and production process. In the early conversations you’ll need to be heavily involved to get the party started. Most factories expect this in the beginning.

However, some factories would like for you to stay engaged and knowledgable about every step through to production. This may even mean having someone at the factory during key steps in the creation calendar. Other factories would rather call you when they are ready to ship the finished goods.

You should know early on if you would prefer to use the WordPress model – do all of the behind the scenes work so you have access to every step of the process – or the Square Space model – use a proven and tested template that you trust will get you to the finish line with tweaks here and there to make it personal.

Six years ago I randomly found a bag supplier on Alibaba to build this waterproof bag with low MOQ. I communicated directly with the factory to build the first 1000 units. Until then I always worked the developers to handle everything beyond design, but I had to do manage everything from materials to importing on this project. I learned a ton.

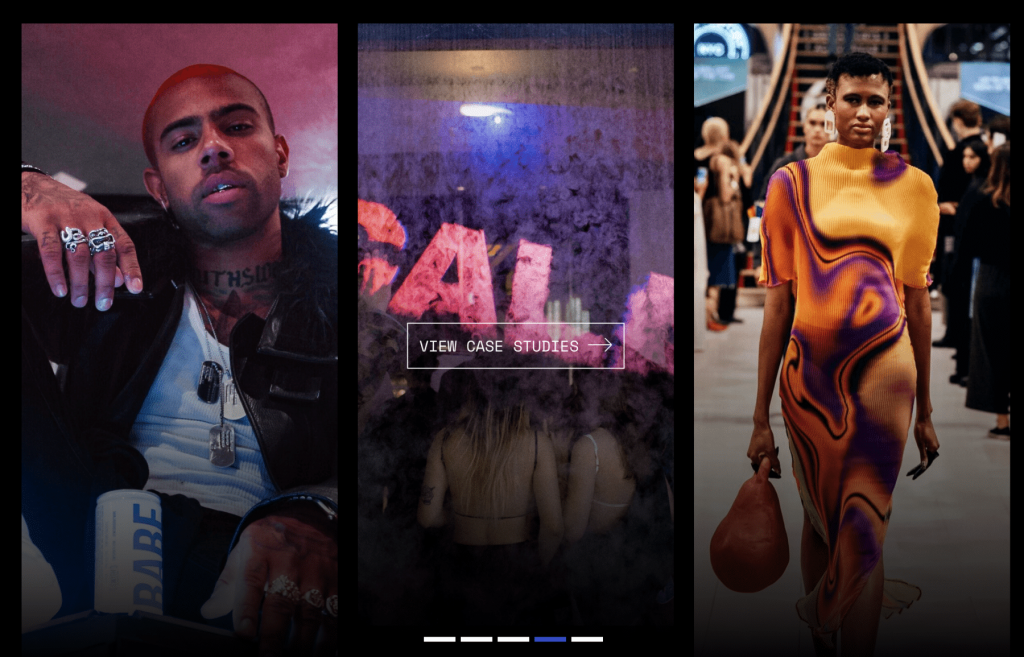

I’ve recently connected with CA.LA, an all-in-one sourcing and production business that works with small companies and individuals to produce apparel and accessory runs. They do all of the work for you and provide you with a quote and potential banks to get your apparel project off the ground.

With larger factories, I’d suggest packing your bags for a couple of weeks at their facility. Like any larger corporation, your project will be competing with hundreds of priorities so you want to assure that time is being devoted to your project. This means that your team will need to spend some time in the factory building and learning as well as enjoying the never-ending meals and parties that will be thrown on your behalf. These dinners used to have many layers with respect to business etiquette, but now they are a simple way to bond with your new partners.

Your’e Probably Not Getting Married

You should ask a million questions when looking for the factory that you will partner with. You should about everything from payment structure to the quality of life for their employees. You should understand that you will spend the next year living with them as you build an amazing family of product together.

You should also understand that most brands don’t stay with the same manufacturing parntner they started with. If you’re extremely lucky, you’ll both grow old together – high school sweethearts. However, most factories that engage with smaller brands do so because they aren’t equipped to deal with larger, more mature brands. And that’s okay. If you outgrow that relationship, you will move on and so will they. Eventually, with maturity and a few relationships under your belt, you’ll meet the right partner. This will be the long term partnership that makes sense for everybody.

Until then, ask a lot of questions and hopefully you’ll make something you’ll be proud to call your first launch (even if the world underestimates how big you might become).

Good things.