While Nike is dealing with a workplace misconduct scandal that has already led to the exits of ten executives, the brand has finally shared how its world famous Air units are made — step by step.

Today, in a report published by the brand, Nike stated that it creates yarn, soles, and basketball courts from recycled plastic bottles. Now, 75% of all its shoes and apparel contain some recycled material. Nike claims that no company uses more recycled polyester than it does, and the brand says that its Air units are among one of its most environmentally friendly innovations.

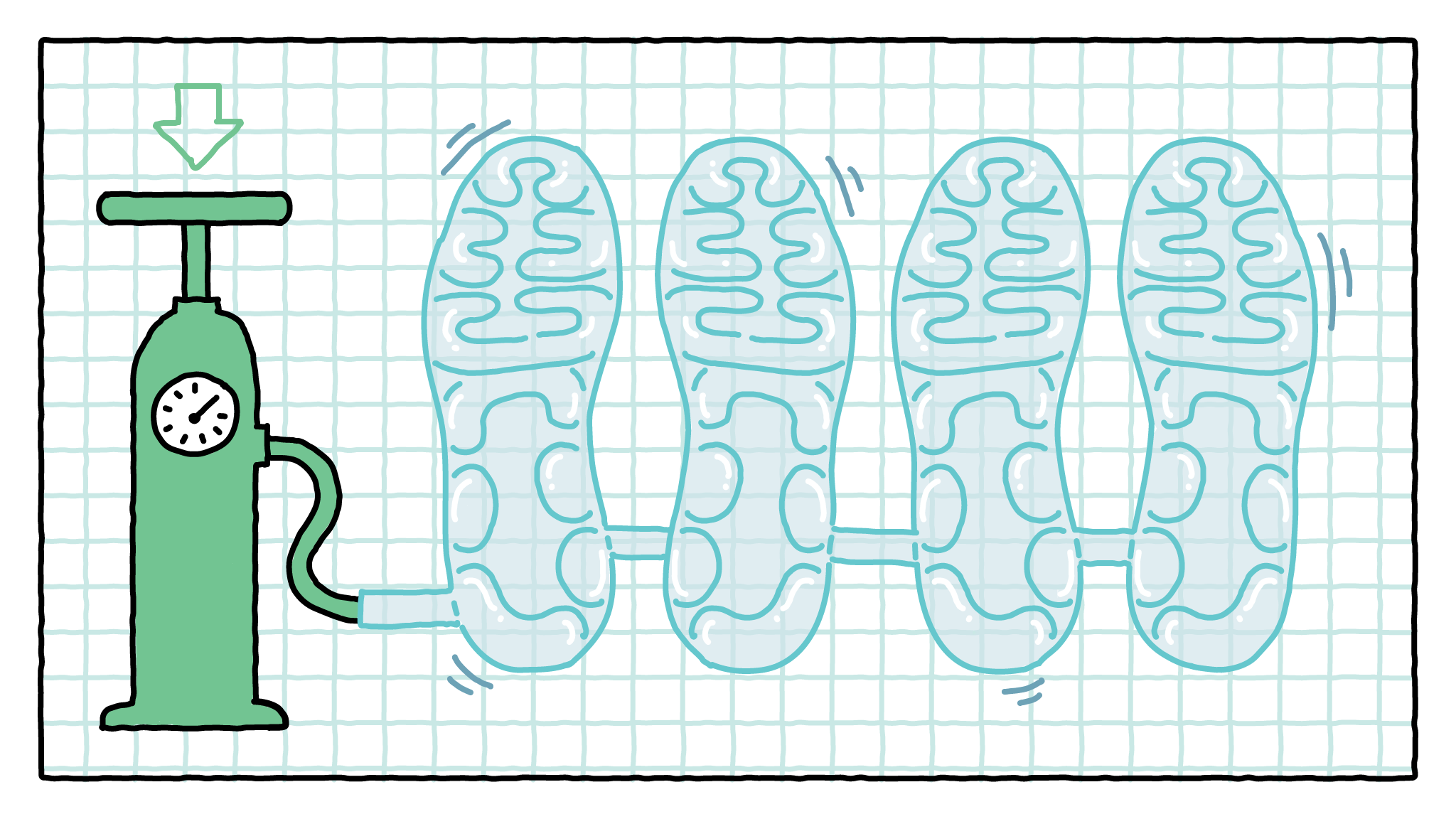

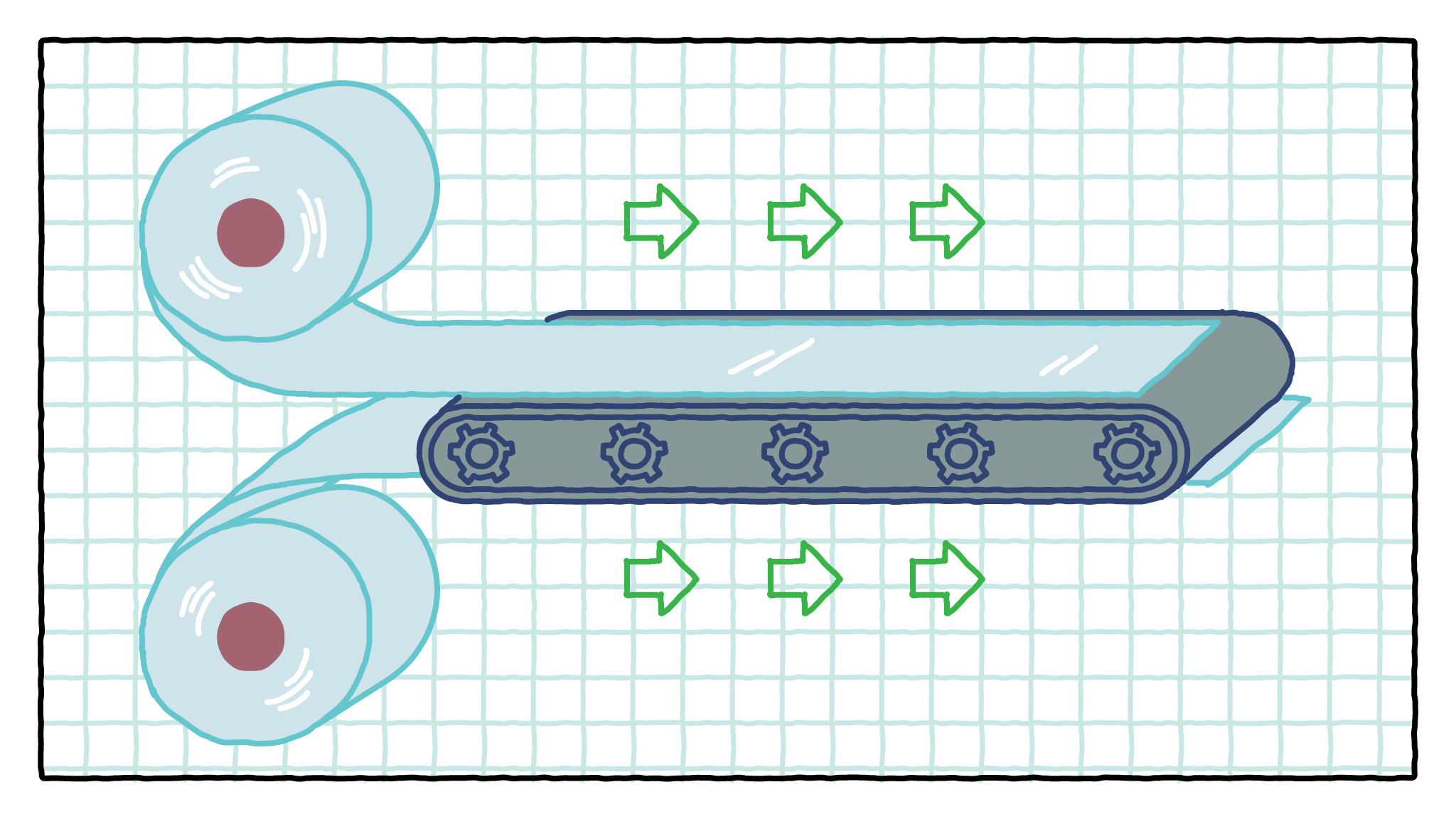

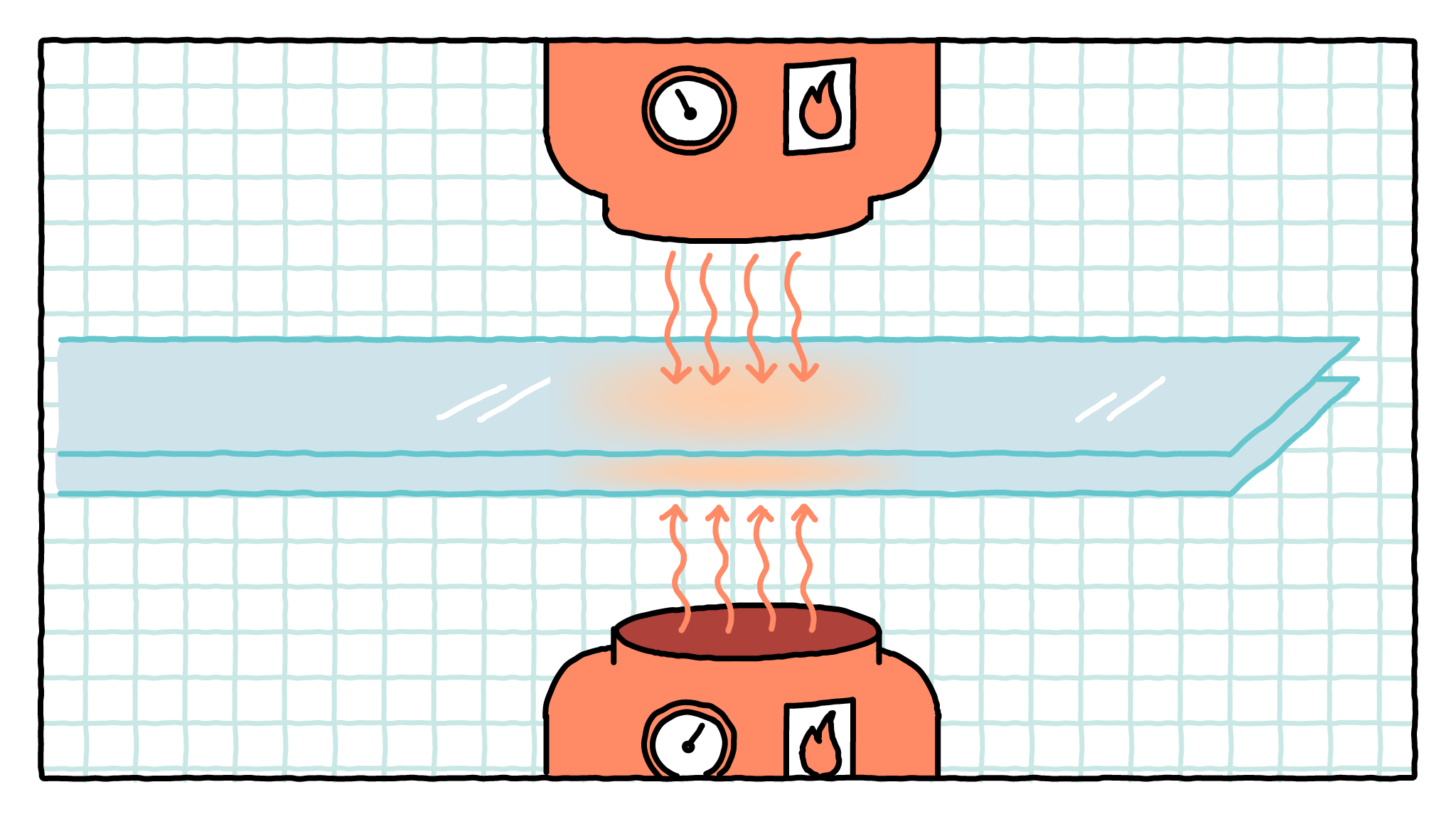

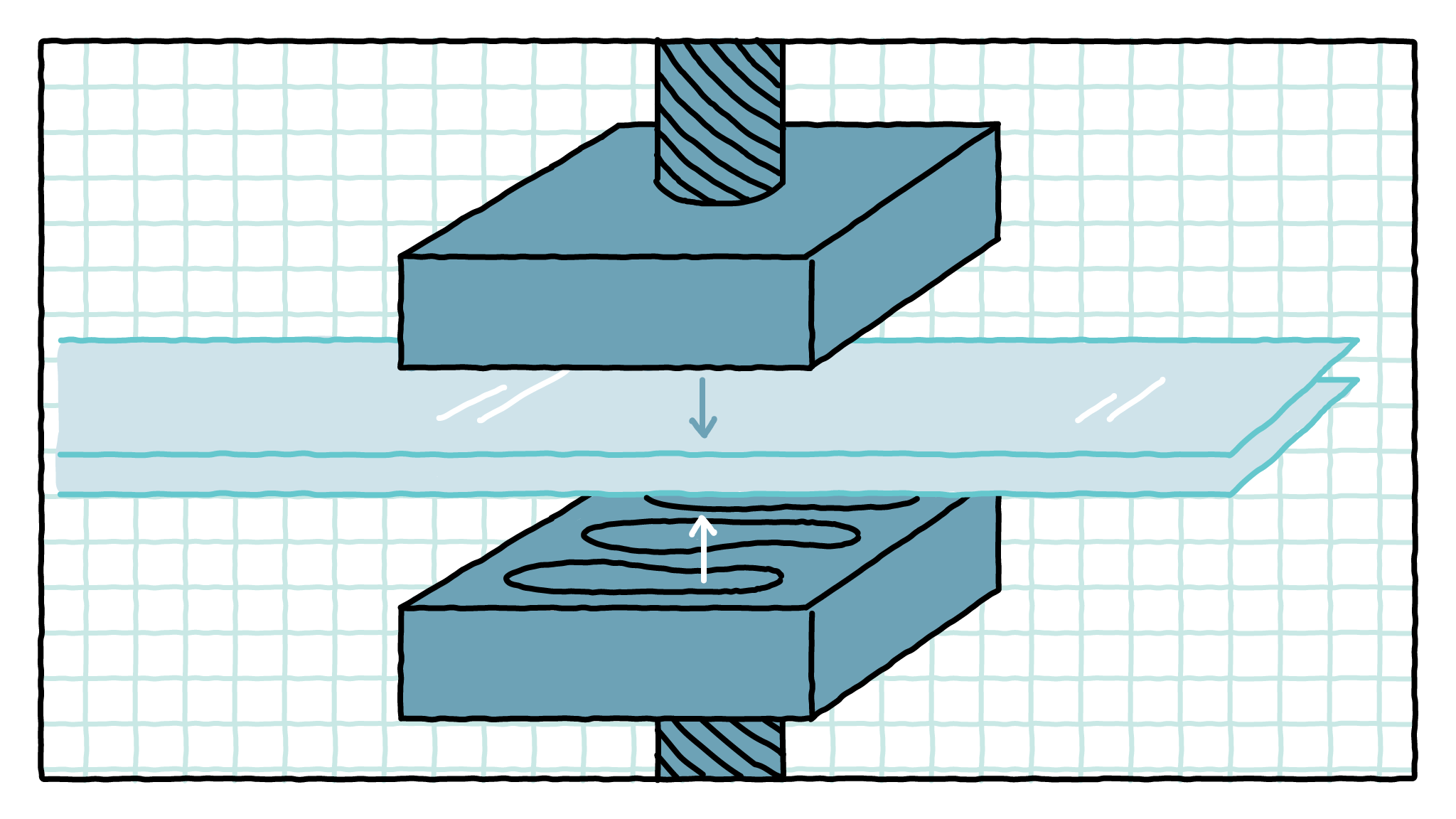

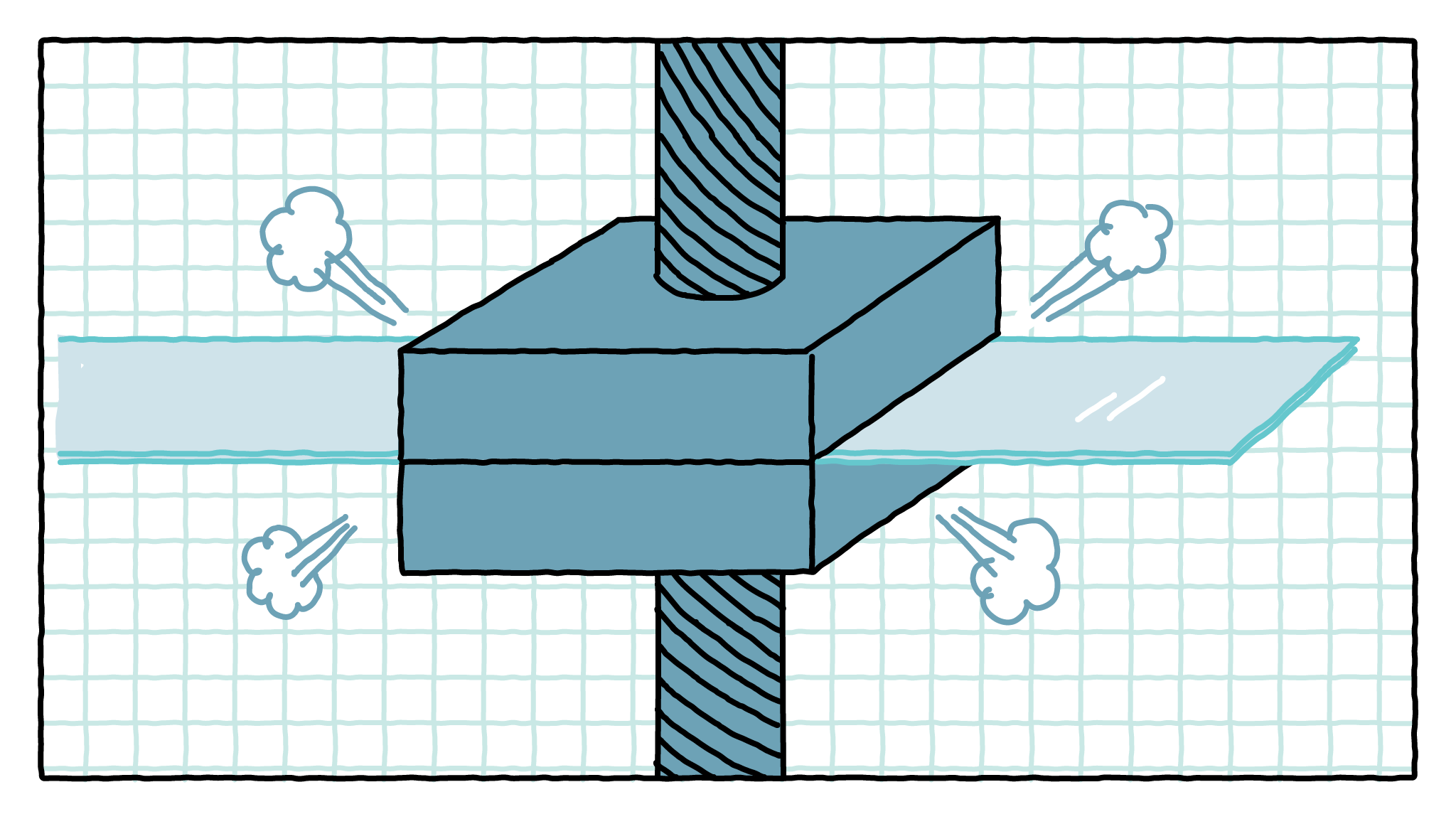

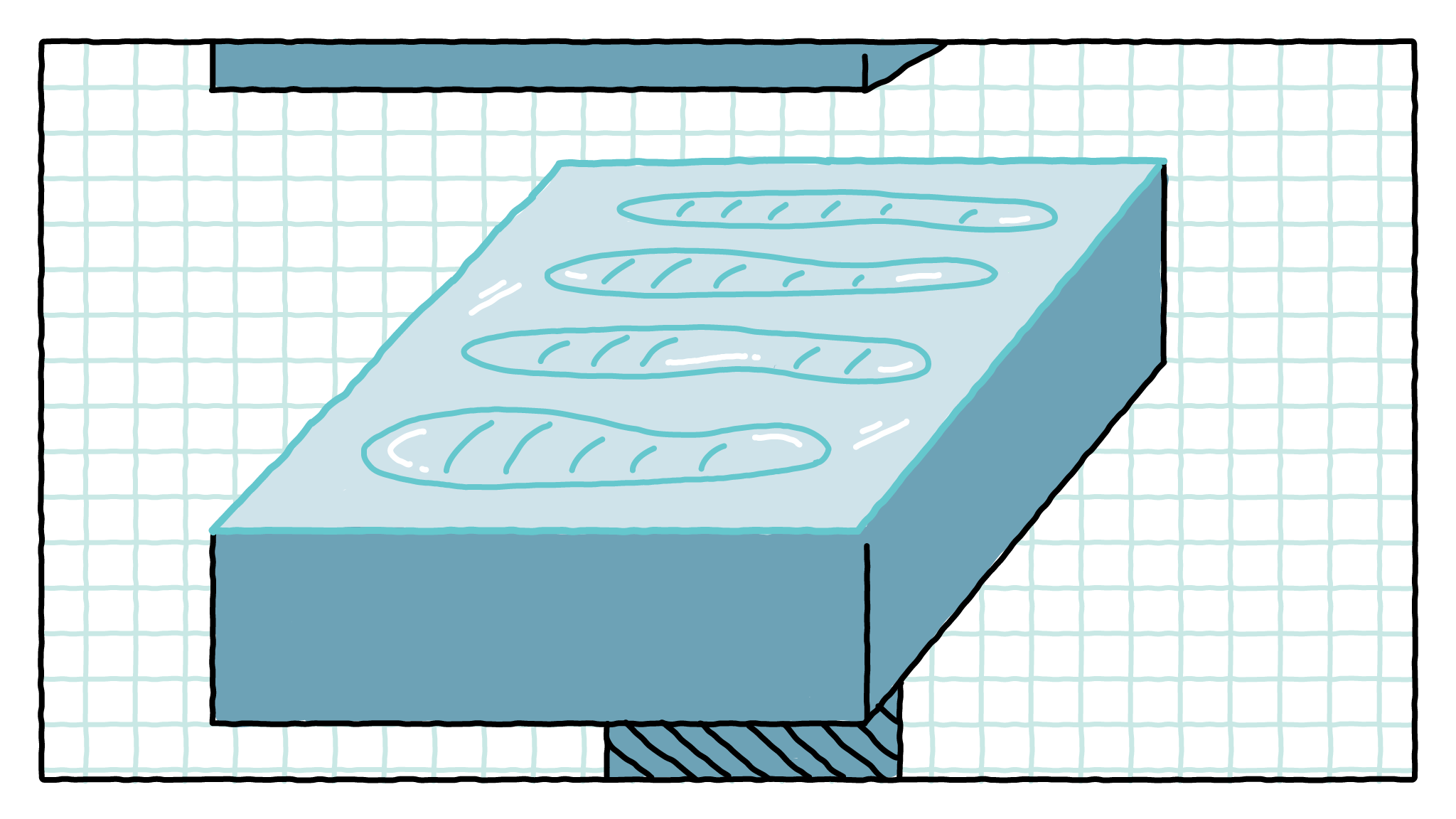

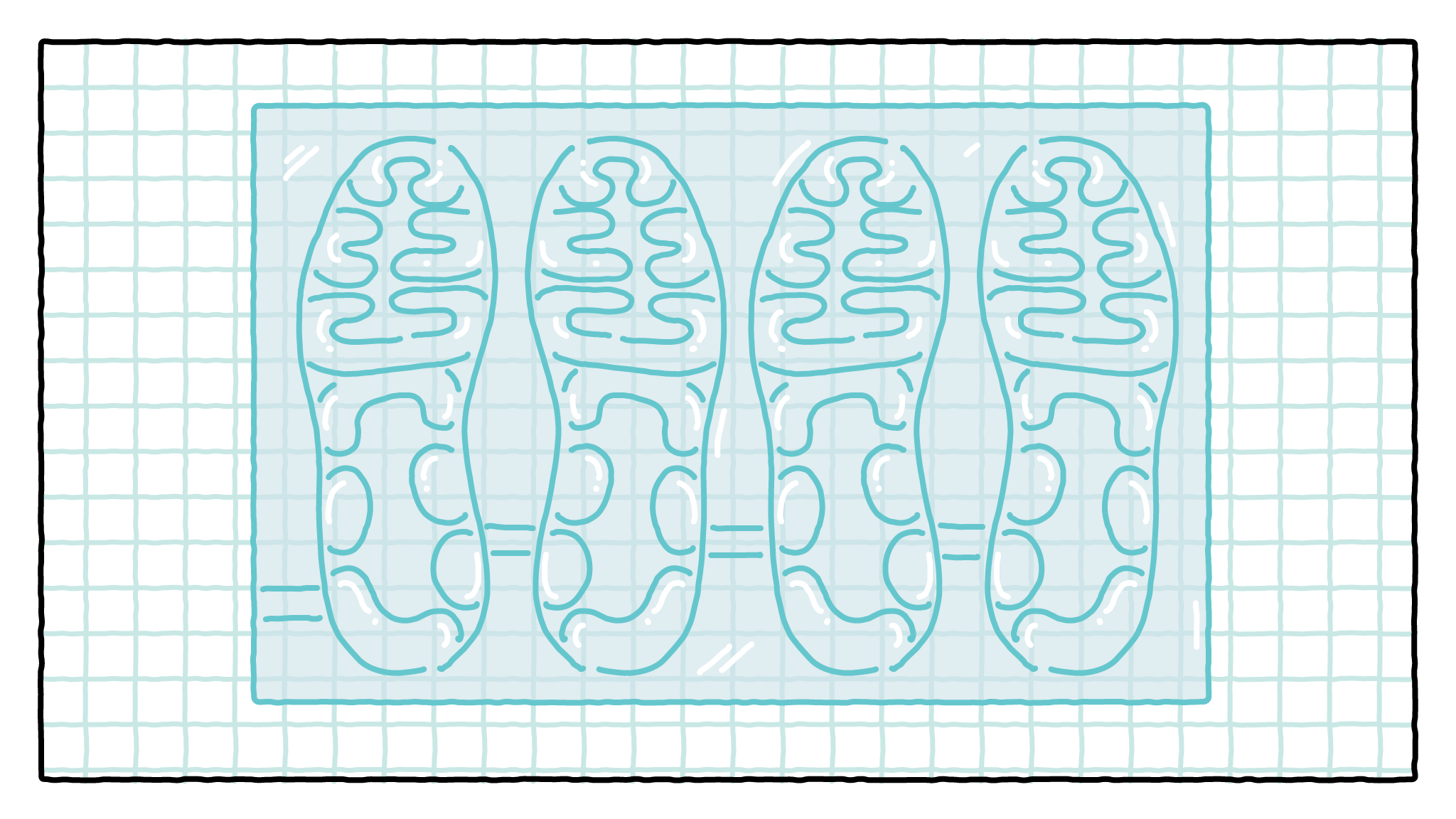

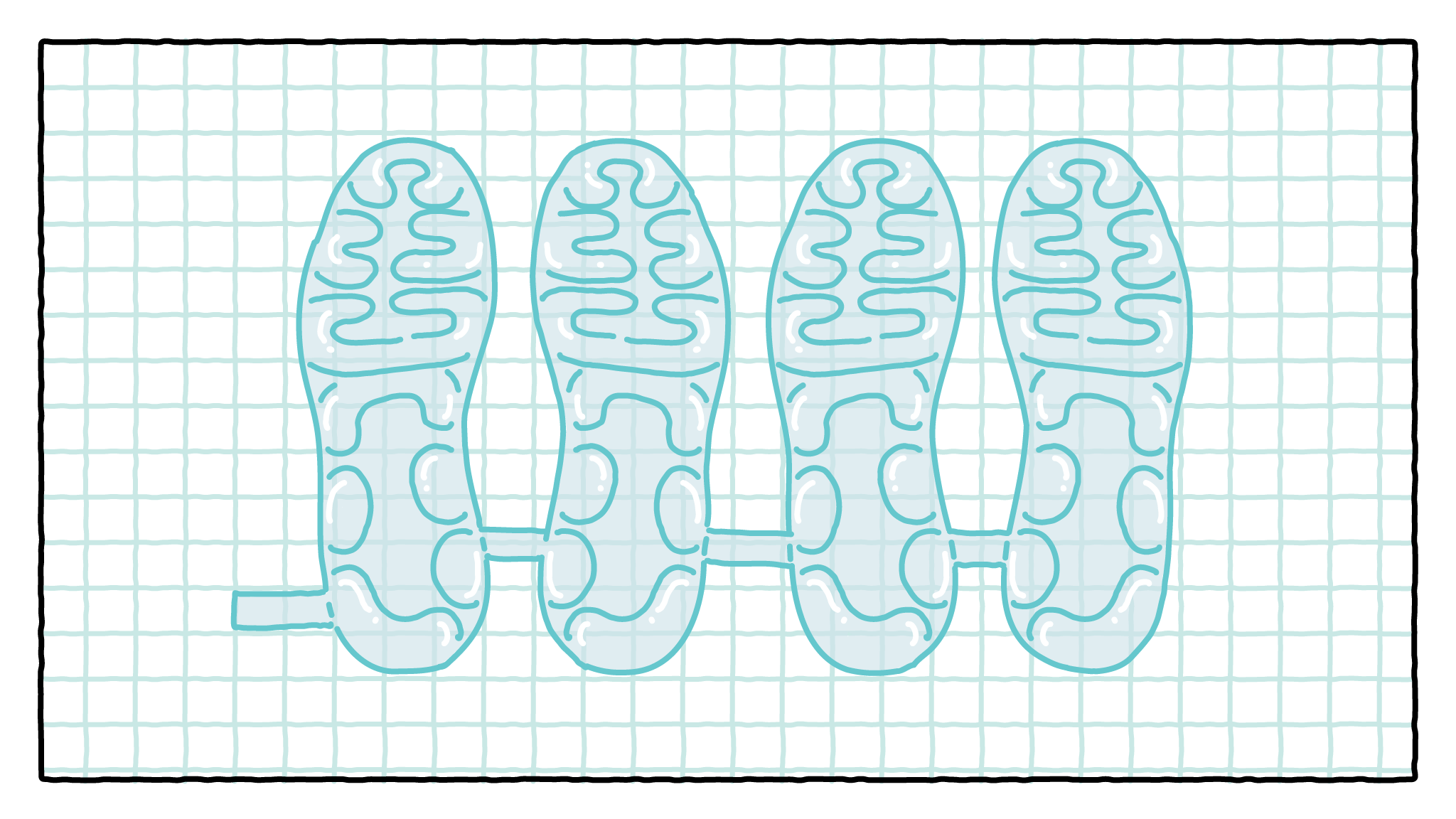

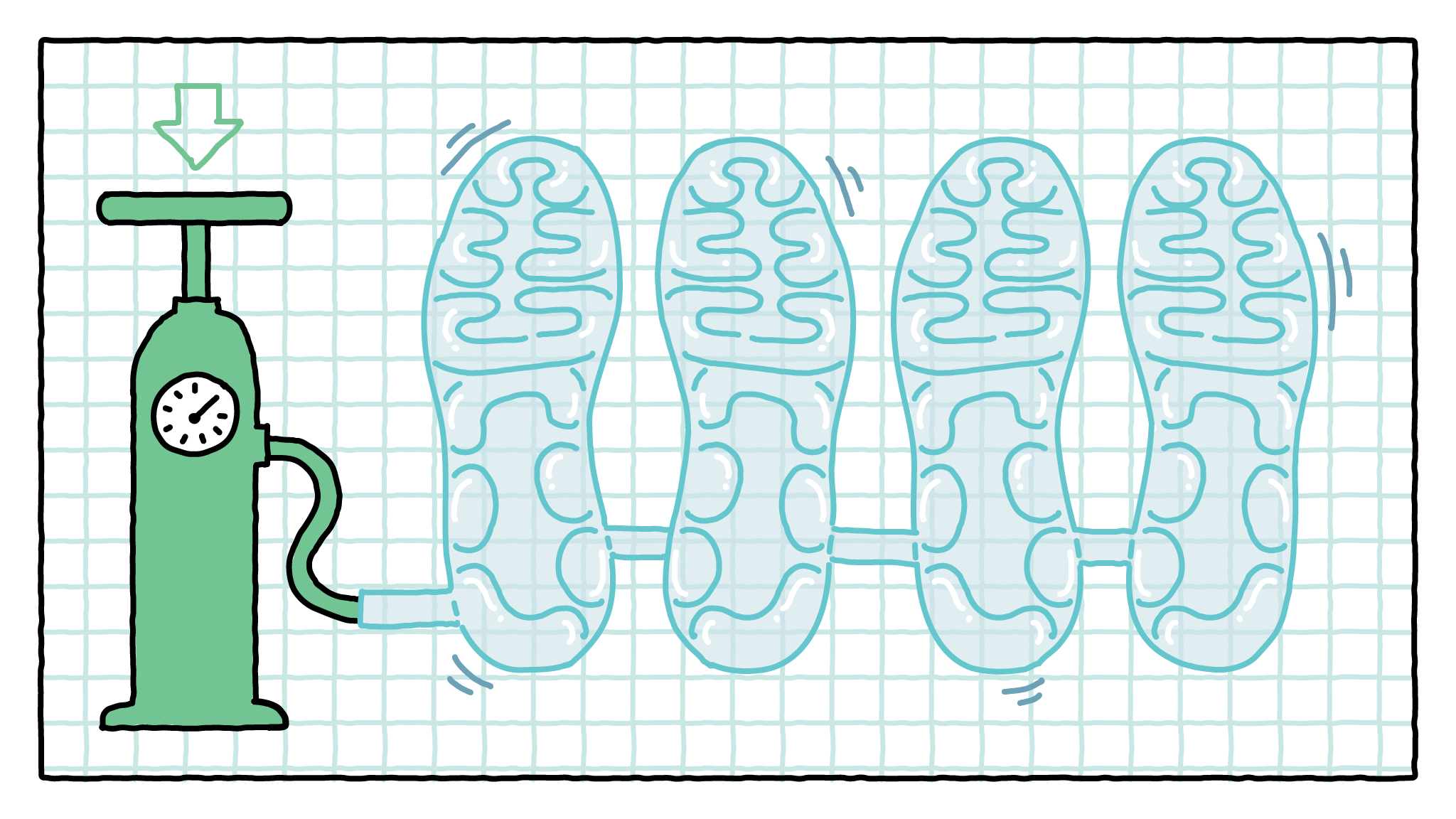

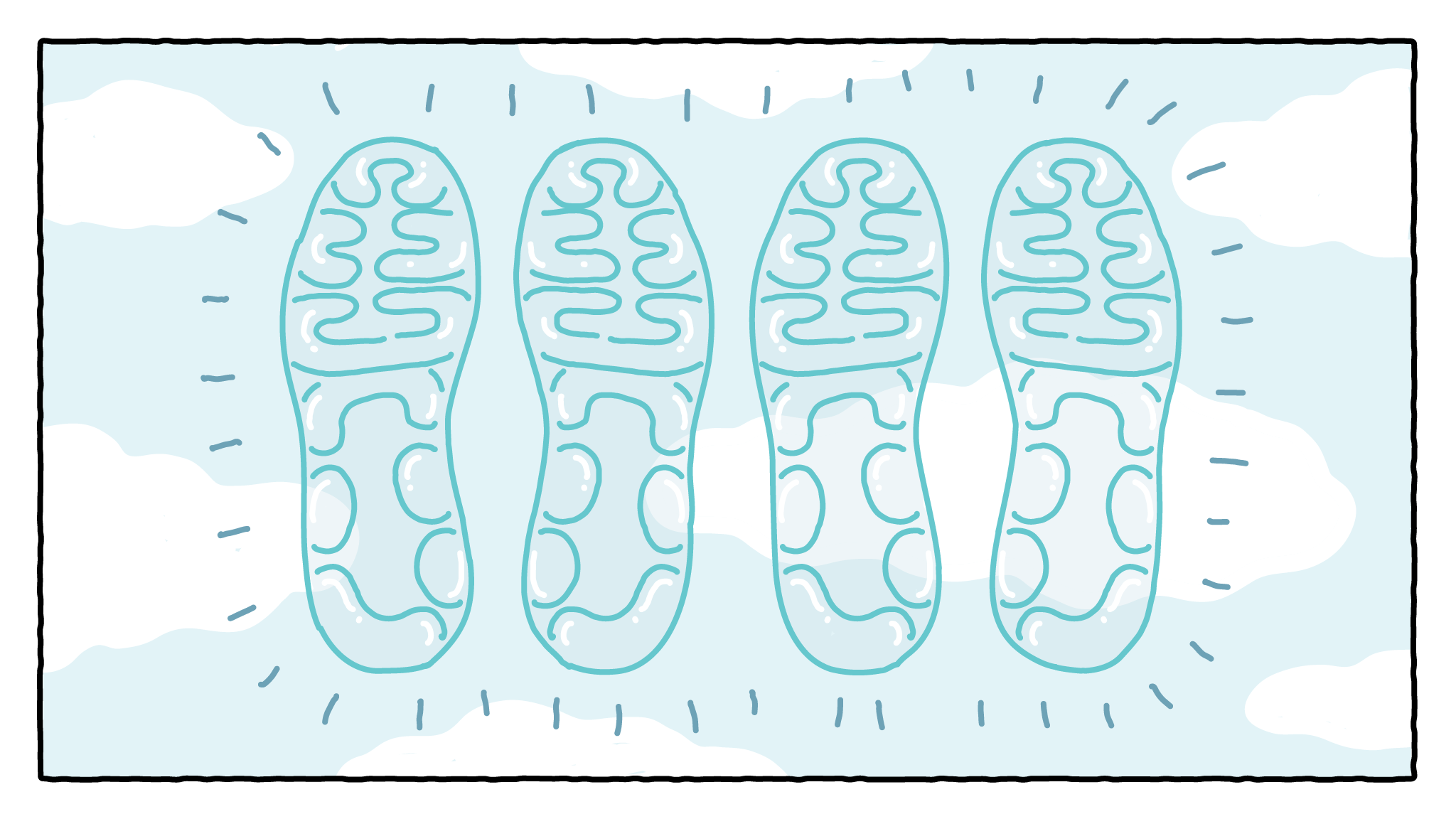

Introduced in 1979 in the Nike Tailwind, the Nike Air unit contains pressurized nitrogen (which is more stable than oxygen or air) within a flexible bag. According to Nike, the dye-coloring process for Air soles allows 99% of recoverable dye water to be recycled. Additionally, the brand claims that all Air sole innovations designed since 2008 are composed of at least 50% recycled manufacturing waste.

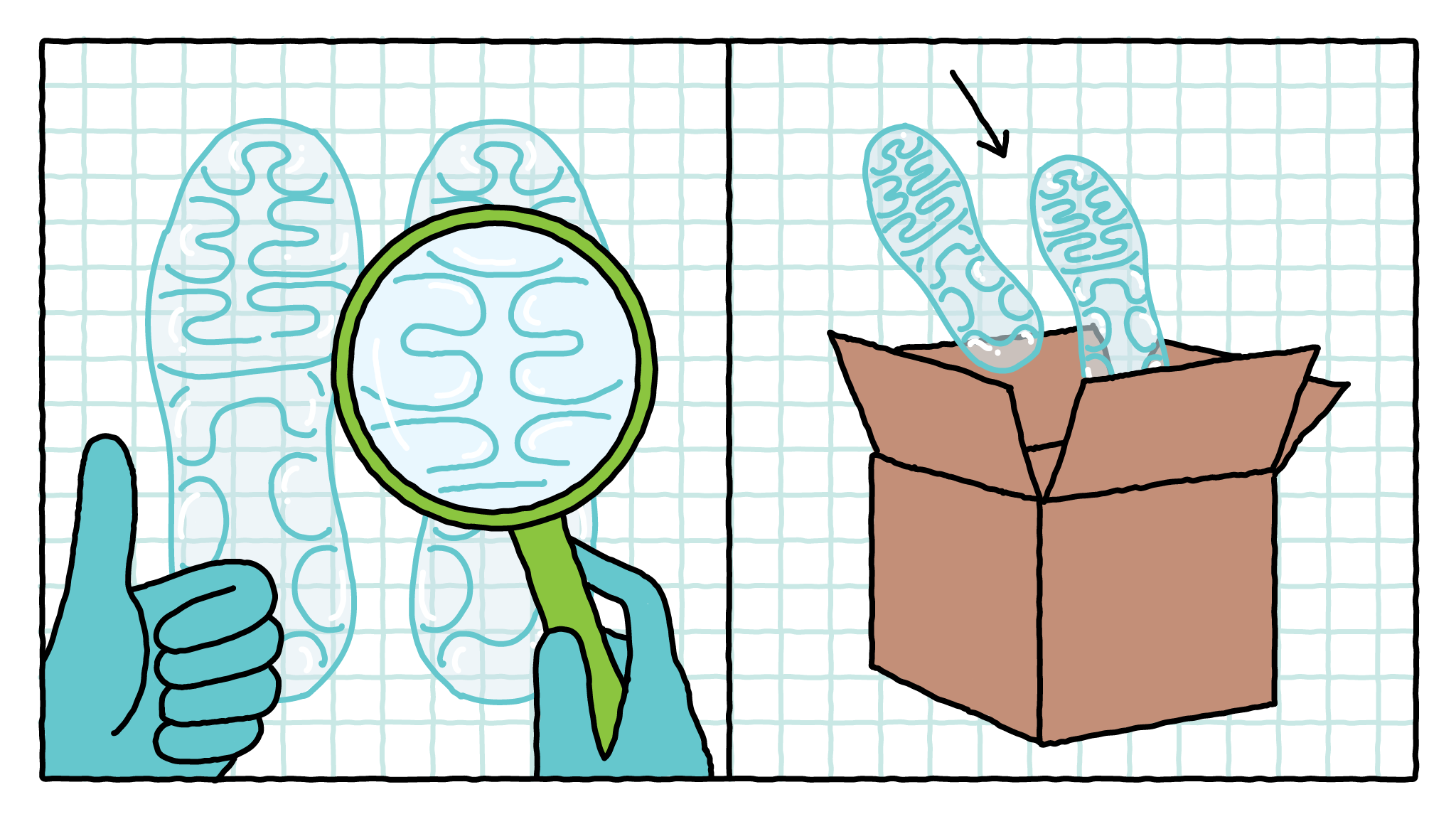

Moreover, the report states that Nike Air Manufacturing Innovation facilities divert more than 95% of manufacturing waste from landfills. Between May 2016 and 2017, Nike diverted 51 million pounds of materials.

One of Nike’s latest sneakers, the Air Max 270 — which has one of the brands largest Air units — uses more than 70% recycled manufacturing waste. The VaporMax Air sole, used on the brand’s top-tier VaporMax footwear line, contains more than 75% recycled material and removes the need for a foam midsole (which further reduces waste).

Nike’s Air units are manufactured in three facilities in the U.S. — two are near the brand’s world headquarters in Oregon, while a third is near St. Louis, Missouri. You can check out the entire Air unit manufacturing process below.

Source: Nike