Nike has released a lot of information about the new Flyweave technology that has been implemented on the Jordan XX9 and Nike CJ81 Trainer. From the sound of the press release, more and more performance models in the Nike Basketball line will feature the technology. Leo Chang even teased the usage of Flyweave on the KD 8, which we’ve predicted would appear since images of the shoe surfaced online.

Read below to learn how Flyweave is made, as well as a comparison to the similar textile known as Flyknit. Share your thoughts by commenting below.

Since the company’s inception in 1972, Nike has perpetually designed technically advanced products while responding to the needs of world-class athletes. This progressive drive was a guiding force behind developing Flyweave, an upper system that fine-tunes support for specific movements.

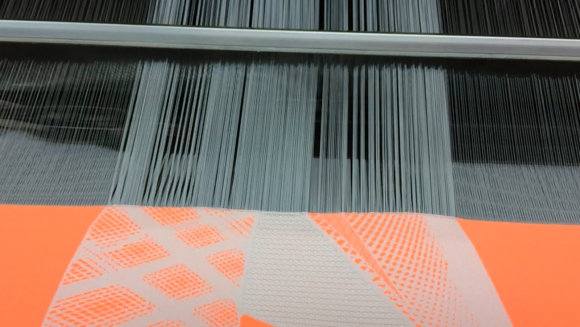

Created through an intricate weaving process, Flyweave technology forms a textile upper maximizing the foot’s natural motion and acting as a second skin. The process of producing a single piece of material shifts shoe construction from the centuries old cut-and-sew method. Flyweave allows Nike designers to account for the durability, strength and stability requirements of individual athletes and sports.

“Weaving enables us to go to space,” says Nike designer Thomas Bell. “Flyweave is one of the most exciting innovations I’ve seen at Nike – inspired from traditional weaving methods, but with the strength and reliability of aerospace materials.”

BORN FROM THE AEROSPACE INDUSTRY

Four years ago, Bell was intrigued by the engineered textiles prevalent in the aerospace industry. The strength, reliability and performance of these products help save lives. Additionally, his experience in intricate bag design featuring a durable nylon piqued his curiosity and prompted his own experiments with the technically woven material.

Sampling countless textile materials in his 12 years working for Nike gave Bell a unique advantage, as he helped refine fabrication techniques. The result of his experimentation birthed what is now known as Flyweave.

TEXTILE DESIGN 101

Textiles are typically developed by either knitting or weaving. Knits specifically have informed athletic shoe design since Nike Flyknit technology debuted in 2012.

Knitting creates multiple loops of yarn, where active stitches produce consecutive rows of interlocking loops. With basic knitting principals as inspiration, Nike Flyknit technology has transformed footwear construction with its ability to reduce waste. Originating in the running department, Flyknit is now common across multiple sports shoes including footwear for baseball, basketball, soccer and training.

Bell leveraged Nike’s collective experience in knit construction to engineer textiles with weaving, a process inherently stronger and more intricate than knitting. Bell has become an expert in the weaving process, which is produced on a loom that interlaces two distinct sets of thread (the warp and weft) to create a textile. A woven seam connects every yarn and has maximum strength for footwear construction.

PRECISION ENGINEERING NOW AVAILABLE

Computer-aided engineering allows designers to customize individual Flyweave uppers by the megapixel. Material modifications allow the addition of small pockets that may be filled for padded comfort or stability. For example, foam cushioning inserted into an open Flyweave pocket on a shoe’s tongue reducing impact to the navicular bone on the top of the foot. Flywire cables can also be integrated into the Flyweave upper’s structure on the medial and lateral sides for added strength and support.

“We have a growing group of designers that have used the technology and are excited by Flyweave’s potential to accomplish even more than we were able to do with the woven upper of the Air Jordan 29 that debuted in 2014,” says Bell.

FLYWEAVE’S PERFORMANCE VERSATILITY

Nike has debuted Flyweave in four prominent shoes over the past year: the Air Jordan 29 (basketball), Nike TW ’15 (golf), Nike CJ Elite TD Cleat (football) and Nike CJ3 Flyweave Trainer (training).

These four shoes tune Flyweave technology uniquely to the demands of very different sports. Across the board, the engineered textile uppers of each shoe provides superior lockdown and containment for lateral movements.

FUTURE OF FLYWEAVE

The future of Flyweave excites many Nike designers, including Leo Chang, Nike Basketball’s Footwear Design Director. Charged with bringing top innovation to hoops, Chang has spent countless hours with Bell collaborating on a new Flyweave constructed basketball shoe debuting in the near future.

“Flyweave offers us an amazing technical advantage in basketball to create incredible strength with a precise, comfortable fit,” said Chang. “We have some exciting news on the way and the response from athletes has even exceeded our expectations.”

While it’s true that some of Nike’s most innovative footwear technologies are based on centuries-old methods of knitting and weaving, trailblazing designers will continue to evolve these methods with materials and construction inherent to Nike’s innovative DNA.

So if jordans performance woven upper is actually flyweave then all the upcoming shoes with the tech will have a price hike being from italy?

Yep labor is more expensive in first world countries than third world

From what I can tell, it’s all technically woven and thus Flyweave. The Jordan performance woven was made specifically in Italy with either different fibers or a different process to allow the various patterns we’ve seen on the 29.

Tinker recently said they were having trouble making a material in Japan/China so they had to make it in Italy. Perhaps the Jordan 30 gets a better version of performance weave with the XX9’s version being left for the Nike line…. Wouldn’t be tough to imagine that Nike figured out how to move manufacturing of XX9’s performance weave from Italy to China as well

This is the pure evidence that Jordan XXX’s (or 30)upper will be made of flyweave. It remains to be seen. I also expect a connection with that NIKECRAFT bag. Shall see. Anyways – good read!

I thought performance woven from Jordan is different from flyweave from Nike.

Maybe this upcoming “new flyweave constructed basketball shoe” is the Jordan XXX? Maybe that’s a hint drop. Maybe their reusing or “refining” the tech, as they would say, for another year on the Jordan flagship. We’ll see.

So the performance woven is not exclusive for jordan? Man

Basically they use plastic coated or glue infused yarn and blow everyone’s mind with the technology that came out of the industrial revolution.

Going beyond that is just advertising jargon